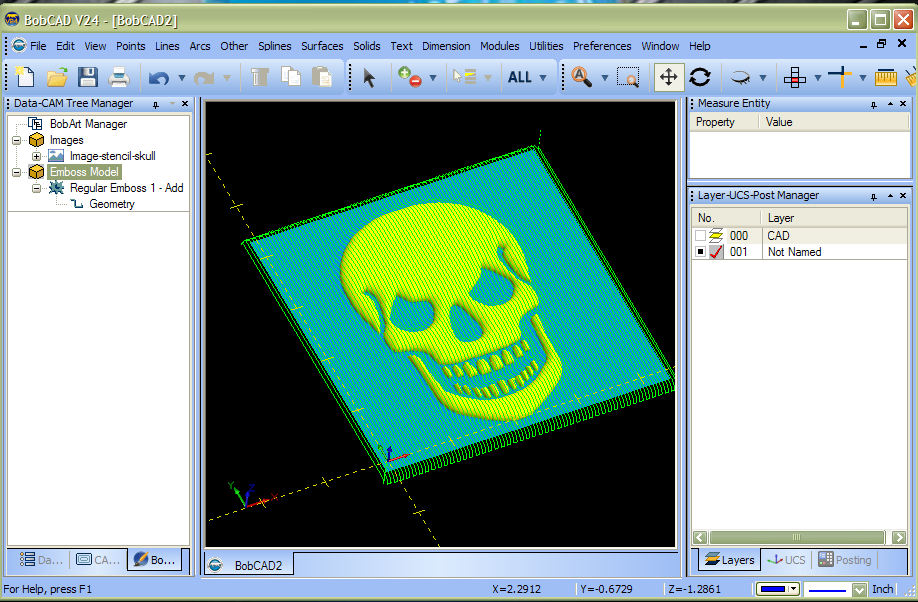

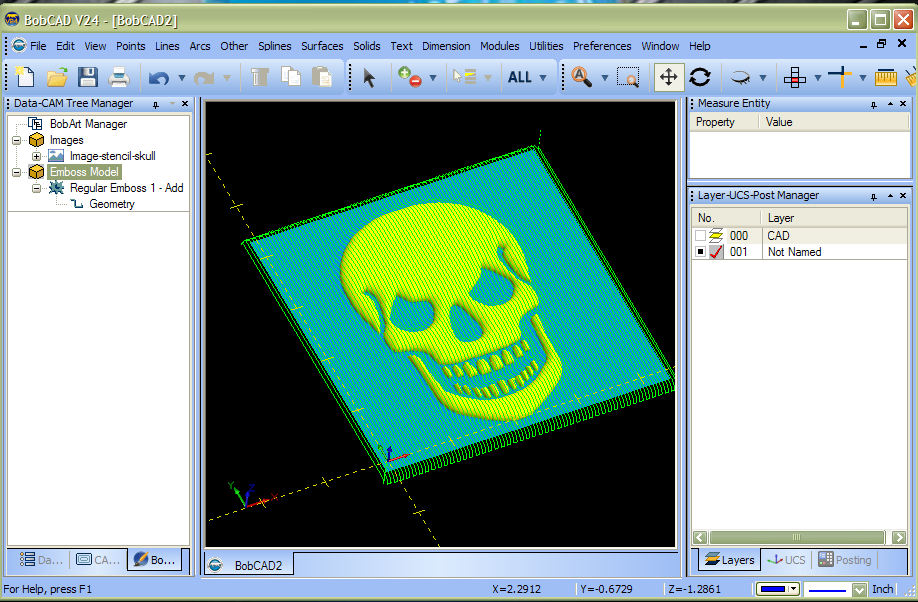

DXF DESIGN & PROJECT PICTURE SHARING FORUMS. WELCOME CENTER, GOOD INFO & MEET OUR SPONSORS. Once the code is generated load the nc file into mach3 and away you go sort of. cheers for now talk soon.Īlso in bobcad you simply tell it what diameter tool you are using and to offset left or right or none and it works out everything for you, no need to offset any part of the drawing. As a consequece the next time they ring me guess what im going to tell them and it starts with f and ends with f. Be aware of bobcad though, they rang me and offered me 3 seat upgrade to v24 last year at a very god price, which i took and the following week released v25. I do run a smoothstepper via usb on computer and now they have sorted out the backlash adjustment problem it works great on chinese lathe and mill. Bobcad does have a post processor editor in v23 which i couldn't find in v24, so i used the v23 editor to edit a processor file to suit my needs and it works perfectly. If you have any questions etc feel free to contact me and i ill try and help. Between the two of them I have no problems running my router, lathe, milling machine and soon to be plasma cutter. I also use mach3 which buy the way I love it is so user friendly once you know wat you are doing. V24 at moment, the one thing I like about it is it will generate machine code direct from drawings and in the order you want etc.

Hi Kevin aussie guy here been using bobcad for round years now. It's the best $20 you'll ever spend, doing plasma cutting. Mach3 then translates the G-code into the motion control for your plasma table.ĭon't hesitate becoming a paying member. Then from the cut path, Bobcad's CAM portion of the software, with the proper post processor installed, generates the G-code file. You might have to generate an offset cut path to compensate for half the kerf thickness (not sure how Mach3 handles offsets). Then do any cleanup and tweaking to suit your needs. In general, you download a dxf and open it in Bobcad. If you just got the Bobcad software and have tech support from them, they should be able to provide you with the proper post processor. Someone else here or on a Mach3 forum or a Bobcad forum may be able to help you configure the post processor. I don't use Mach3, but you will need a post processor for the CAM part of Bobcad to configure the G-code the way that Mach3 wants it. We use version 21 for most plasma cutting jobs now.

We have a love / hate relationship with Bobcad. I've used it for over twenty years with several CNC machines.

0 kommentar(er)

0 kommentar(er)